After the first season my home-made bike trailer has been kicking ass in a big way. I’ve hauled some seriously heavy loads and used it lots of times that I would have previously used my car. Costco runs are a breezy bike ride through fields of freshly mown grass instead of stuck at red lights. Forget going around in circles looking for a spot in the Ikea parking lot: the bike rack right next to the door. I’ve also made improvements to the design as flaws with the first version came to light.

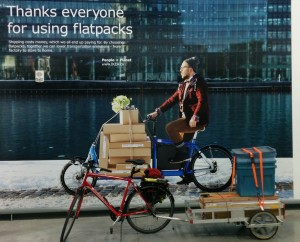

The first really heavy load that I carried was to get furniture from Ikea. We had two new people starting at the office, and as the office clerk (among my many positions) I needed to get two new desks, chairs, wastepaper baskets etc.

A nice thing about Ikea is that they list the weights of all the items on the boxes, so I could tell right away that I was carrying about 250 pounds. I didn’t have to get too far to see that the trailer was having problems. The wheels were cantilevered out on axles made of 3/8″ threaded rod, and the axles couldn’t take the weight and were bending so that the wheels started rubbing against the sides of the trailer. Not enough to slow me down, and when I got home I just bent them back. Also, it started to rain, and the spray from the trailer wheels was flying all over the boxes; the cardboard was getting soaked. Ideally I would add fenders of some kind.

I took the trailer out at least once a week, to get groceries, bring my 4 (car) tires to be replaced, buying new computers for the office, and the aforementioned Costco runs.

Above is an example with about 200 pounds of groceries. Yes, I weighed the load on my bathroom scale when I got home; one of the side effects of cargo trailers is that it’s fun to see just how much you can carry. As time went on though, the axles were taking a beating, and the bearings were wearing out. Remember that I got the wheels from a kid’s bike, and they were designed to carry about 30 pounds, not 200. It was time for a design improvement.

I got new wheels from Wike, an excellent Canadian company, that used a 1/2″ axles instead of 3/8″ with bearings that would hold up to heavy loads. More importantly, I built a subframe for the wheels so that they were supported on both sides. The overall increase in weight was negligible, but the increase in strength and stiffness was amazing. I was tempted to put rubber discs between the trailer body and the wheel subframe, but figured that the air in the tires would soften the ride enough.

I also decided to move the tires backwards a bit, so that if I wanted to carry an adult sitting in the trailer (see below) or lumber that extended past the end of the trailer (see further below) that the weight would be centred over the wheels.

The nice thing is that it was super easy. The only tools that I needed were a drill, a hack saw, and a wrench.

Now I was ready for some serious hauling. The next thing that I made was a wooden body to turn my simple cargo trailer into an elegant chariot fit for a queen, which I could use to bring my mother in law out on family bike rides. She had never learned how to ride a bike, so any time that we wanted to go out as a family we would have to take the car unless she stayed home. Thankfully, no more! One less reason to need a car.

It was around this point that I pretty much decided that I would no longer take my car to get stuff anymore, Now I was regularly carrying 200 pound loads plus carrying my daughter on my home-made passenger seat.

It felt amazing getting all this stuff done under my own power.

Then came the moment that I think I reached the limits of what was possible. We are finishing our basement, and needed to install new flooring. When it was time to pick up the laminate flooring, I figured, why be lame-ass, when I could be hauling ass?

Folks, what you see there is about 400 pounds of flooring. The trailer weighs about 40 pounds, I weigh 170, and my bike is about 30, so in all it was close to 650 pounds of weight that I was propelling, 15 km from the big box reno centre to home. It took about an hour to get home, so the speed was ok overall.

Folks, what you see there is about 400 pounds of flooring. The trailer weighs about 40 pounds, I weigh 170, and my bike is about 30, so in all it was close to 650 pounds of weight that I was propelling, 15 km from the big box reno centre to home. It took about an hour to get home, so the speed was ok overall.

Luckily Ottawa is mostly flat, with a lot of segregated bike paths, so the ride wasn’t too bad. I just had to take my time, especially when it came to stopping. I figure that it was how a train must feel… Once I got up to speed it didn’t take much more effort to pedal, but starting or stopping were a Big Deal.

Unfortunately though, the next day I found out that my bike’s rear axle had gotten bent along the way; the constant torque was too much. I replaced the rear axle thanks to a few twitter bike friends and the folks at re-cycles, a community bike shop that lets people come in to work on their bikes.

Since then I’ve been keeping the loads lower and things have been fine. Overall, the trailer has been exceptionally useful and totally worth the initial effort.